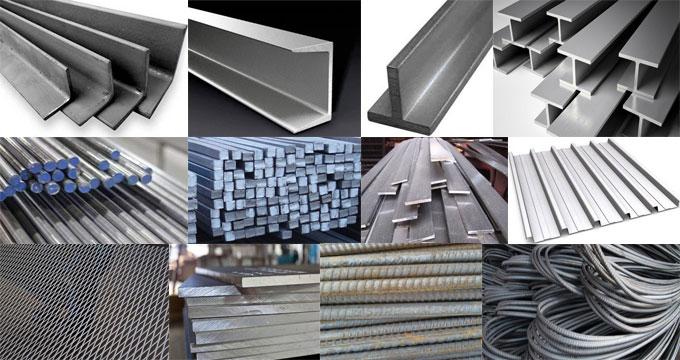

Stainless steel is a versatile and durable material widely used in various industries. Its corrosion-resistant properties, high strength, and aesthetic appeal make it a popular choice for applications ranging from kitchen utensils to industrial machinery. However, there are numerous grades and types of stainless steel available, making it essential to select the right one for your specific needs. There is many stainless steel exporter in morocco but this guide aims to provide you with important considerations to help you choose the appropriate type of stainless steel for your project.

1. Understanding Stainless Steel Grades

Stainless steel grades are classified based on their chemical composition, with different grades offering varying levels of corrosion resistance, strength, and heat resistance. The most popular grades include 304, 316, 430, and 201. Each grade has its unique attributes and is suitable for specific applications. It is crucial to understand the differences between these grades to make an informed decision.

2. Determine the Corrosion Resistance

Corrosion resistance is a primary characteristic of stainless steel, and it varies depending on the grade and environment in which it will be used. Assess the intended application and identify the corrosive elements it may encounter, such as acids, moisture, or saltwater. For instance, if you require stainless steel for marine environments, look for a grade with high resistance to chloride corrosion, such as 316 stainless steel.

3. Consider Strength and Durability

The strength and durability requirements of your project play a vital role in selecting the appropriate stainless steel grade. Grades such as 304 and 316 are known for their high strength and are typically used in applications that demand structural integrity, such as construction or automotive components. However, it is important to note that higher strength grades may come at a higher cost.

4. Evaluate Heat Resistance

If your project involves high-temperature applications, it is crucial to consider the heat resistance of the stainless steel grade. Some grades, such as 310 stainless steel, are specifically designed for use in extreme temperatures and excel in applications like furnace parts, exhaust systems, and industrial ovens. Assess the maximum temperature your stainless steel will be exposed to and select an appropriate grade accordingly.

5. Aesthetic Appeal

While not the primary consideration, appearance might be important depending on your project. Stainless steel comes in various finishes, including brushed, mirror, or matte, enabling you to choose one that suits your design requirements. Additionally, specific grades, such as 430 stainless steel, can be highly polished for enhanced aesthetics. Keep in mind that highly polished finishes may require more effort to maintain their appearance.

6. Cost Considerations

Stainless steel price is an important factor when selecting a stainless steel grade. Higher-quality grades with exceptional resistance and strength usually come at a premium price. Evaluate your budget constraints and strike a balance between performance and cost-effectiveness. In some cases, it might be more economical to choose a lower grade with an appropriate level of corrosion resistance and strength, as long as it meets the requirements of your application.

7. Research Trusted Suppliers

Look for reputable and reliable suppliers who specialize in selling stainless steel. Check their website, reviews from previous customers, and ratings on reliable platforms. Take note of their experience in the industry and their certifications, as this can indicate their commitment to quality.

Conclusion

By considering these key factors – corrosion resistance, strength, heat resistance, aesthetic appeal, and cost – when selecting a stainless steel grade, you can ensure that the material chosen aligns perfectly with your project’s requirements. Remember to consult with stainless steel suppliers, engineers, or industry professionals for expert advice, as they can provide valuable insights into the ideal stainless steel grade for your particular application.