In the dynamic world of industrial heating, the finned strip heater stands out for its versatility and efficiency. These heaters are crucial in a wide range of applications, from air heating to process heating in various industries. This 800-word blog post delves into the world of finned strip heaters, exploring their design, applications, advantages, and the future trends that are shaping their use.

Understanding Finned Strip Heaters

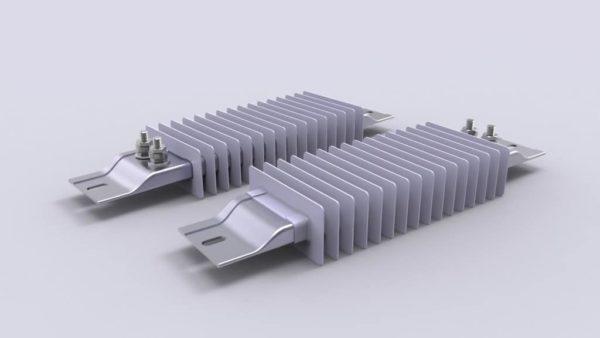

These heaters are a type of electrical heating element that consists of a metal strip, typically made of stainless steel or aluminum, with attached finned coils. The fins increase the surface area of the heater, allowing for more efficient heat transfer to the surrounding air or gas. This design makes them highly effective for applications requiring a uniform heat distribution over a large surface area.

Design and Construction

The construction of finned strip heaters is robust and designed to withstand harsh industrial environments. They are often encased in a sheath material like stainless steel, which provides excellent corrosion resistance. The internal heating element is insulated, ensuring safety and improving heat retention. The fins, usually made from aluminum, are attached at regular intervals along the strip, enhancing the heat dissipation efficiency.

Versatile Applications in Industry

Finned strip heaters are employed in various sectors due to their adaptability and efficient heating capabilities. Some of the key applications include:

-

Air Heating: In HVAC systems, these heaters are used for rapid air heating in ducts and through forced air systems. They are essential in maintaining controlled environments in commercial and industrial buildings.

-

Process Heating: They play a vital role in process heating in industries such as plastics, packaging, and food processing. For example, in the plastics industry, they are used to heat hoppers and extruders.

-

Freeze Protection: These heaters are also used to prevent freezing in outdoor equipment, pipelines, and tanks, ensuring continuous operation in cold climates.

Advantages Over Traditional Heating Elements

The benefits of using finned strip heaters are numerous:

-

Efficient Heat Transfer: The fins increase the surface area, allowing for more efficient heat distribution compared to traditional strip heaters.

-

Durability: Their robust construction makes them suitable for use in harsh industrial environments, providing a longer service life.

-

Uniform Heating: They offer more uniform heating, which is crucial in processes where consistent temperature is key to product quality.

-

Flexibility in Installation: Finned strip heaters can be installed in various orientations and locations, making them a flexible solution for different heating needs.

Energy Efficiency and Cost-Effectiveness

One of the significant advantages of strip heaters is their energy efficiency. By providing targeted and uniform heating, they reduce the energy required to maintain the desired temperatures, leading to cost savings. This efficiency is particularly important in industries looking to reduce their energy consumption and carbon footprint.

Customization and Integration

Finned strip heaters can be customized in terms of size, shape, power ratings, and control options to suit specific industrial applications. This customization allows for seamless integration into existing systems, enhancing the overall efficiency of the process.

Safety and Maintenance

Safety is a paramount concern in industrial heating, and finned strip heaters address this with features like overheat protection and robust insulation. Regular maintenance and checks ensure their longevity and consistent performance, minimizing downtime in industrial processes.

Future Trends and Innovations

The future of strip heaters lies in the integration of advanced technologies:

-

Smart Controls: Incorporating IoT and smart controls for precise temperature management and remote monitoring.

-

Improved Materials: Ongoing research into better materials for higher efficiency and longer life spans.

-

Sustainable Practices: Focus on eco-friendly designs and materials to align with sustainable industrial practices.

Conclusion

Finned strip heaters are a cornerstone of industrial heating, offering versatility, efficiency, and reliability. Their ability to provide uniform and targeted heating in a variety of applications makes them indispensable in modern industrial processes. As industries continue to evolve, the demand for efficient and sustainable heating solutions like these heaters is only set to grow. They are not just tools for heating but catalysts for innovation and efficiency in the industrial world.